Tab Bonding Machine LCD Repairing 100 Inch TV 45Psi - 75Psi Working Pressure

| Place of Origin: | |

|---|---|

| Brand Name: | |

| Certification: | |

| Model Number: |

| Min Order: | |

|---|---|

| Packaging: | |

| Delivery Time: | |

| Payment Terms: | |

| Supply Ability: | |

| warranty: |

| Brand: | ASCEN | Working Pressure: | 45-75psi |

|---|---|---|---|

| Approval: | CE ISO | Application: | TV Repair TAB Bonding |

| Warranty: | 2 Year | Weight: | 550kg |

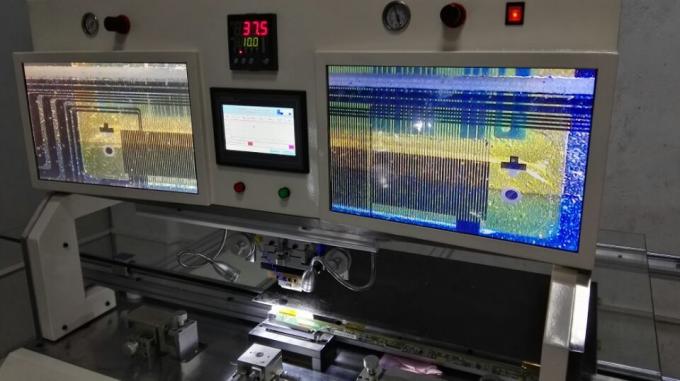

Tab Bonding Machine LCD Repairing 100 Inch TV 45Psi - 75Psi Working Pressure

Large Size LCD TV Panel TAB Bonding Machine Quick Overview:

According to maintenance staff tailored high-end products , machine not only in the accuracy of the temperature and the mechanical accuracy do the precision design , the procedures also increases the glass and circuit board parameters direct selected function , working pressure automatically switch , greatly facilitate the technical staff selected the parameters , increased the tool bit preheating function , to ensure that the machine at any temperature difference can ensure heating rate and temperature accuracy , the bonding effect reached factory-class level , high bonding excellent rate, low repair rate , this machine is the maintenance and after-sales staff preferred the classic model.

All the LCD TV Panel Problems ,like dark dot,horrizon line,vertical line and so on,all the problem unless the broken crack LCD Screen.

tv bonding machine data :

Our factory have two model TAB Bonding Machine for LCD TV Panel Repair,both of them suitable for FPC, COF, TAB and LCD Panel, PCB bonding.Below is some of their characters,can repair LCD TV Screen size up to 100 inch.

| Model | ||

| Head NO. | 1 | 2 |

| Panel thickness | 0.3mm-1.1mm(single layer glass) | |

| IC No. | Multi/panel | |

| Bonding direction | X or Y | |

| Boning time | TFT, 1.8s/chip | |

| Capacity | TAB, 380 pcs/H | |

| Bonding accuracy | ±1.5um | |

| Positioning accuracy | ±0.5um | |

| Working environment | Clean, dust free | |

| Air pressure | 0.5-0.7Mpa | |

| Automatic pressure | Multi pressure, max 10 segments | |

| Input | AC220V/50Hz | |

| Power | 1200W | |

| Pneumatic parts | Japan SMC MXS20-75/MXS20-100 | |

| Heating method | Pulse heating | |

| PID temperature system |

Brand: Japan AZBIL Model: C36TV0UA1200 |

|

| Hot head |

Material: Japan titanium alloy Size: 45*1.4*10 Plane precision: 0.001mm Plane thickness: 0.5mm |

|

| Thermocouple | K type, origin USA OMEGA | |

| Controller | Japan Panasonic PLC | |

| Image system |

Japan Panasonic image system COF positioning: down positioning PCB positioning: Yes Camera quantity: 3 Microscope: 30-120 zoom COF monitor: 19” * 2 PCB positioning monitor: Yes Up light: Yes Down light: Yes |

|

| COF fine adjustment |

Origin: Taiwan Guide rail type: U type Accuracy: 0.01mm Adjust direction: X/Y/R R range: Rough adjustment 360°; Fine adjustment ±5° |

|

| Camera fine adjustment |

Control: X/Y/Z micrometer Focus adjust: manual |

|

| Alarm |

Air pressure fault; Temperature fault; Thermocouple fault; Operation fault |

|

| Hot head positioning | Any positon | |

| Parameter memory | Multi parameter group storage | |

| Size | L1800*W1200*H1520mm | |

| Weight | 450kg | |

LCD TV Screen Repair Thermode Soldering Working Principle: A. The system is used to control the Panasonic: In the PLC,we have preset all the tv brand technical parameters,you dont have to set any data when you deal with different brand tv,just need to change the brand button on the lcd display. Save the market of the brand TV Repair required parameters like Samsung, LG, Sharp, Sony,Toshibo,Philip,Zenith,JVC,CMO, AUO, bright star, Hitachi, HannStar, Huasheng, Chinese, etc.. The four section temperature set points, the first section temperature, initial temperature of second section temperature, cooling temperature. PLC and touch screen communication, according to the function of automatic control in the production process of production expansion. System of automatic detection, alarm display function, make the equipment maintenance more convenient. B. The inlet temperature sensing line and the new Panasonic temperature chip (TC2) to make the temperature control more accurate, with heating time, temperature higher precision, and the addition of synchronous display temperature curve and parameters. C. 6.5 inch intelligent man-machine interface, programmable logic controller (PLC) control system, stable operation of the device, reliable. D. Compared with consistent temperature lcd tv panel repair,we use pulse heating,which is more quick heating and cooling during bonding.

Fast heating / cooling and secondary cooling function. High quality titanium alloy head, automatic temperature compensation function, so that the temperature is more accurate. E. The Alignment bench micrometer ensure machine High precision alignment:

Equipped with advanced optical alignment system, fully meet the product clear alignment and production precision, para X, Y, Z axis adopts high precision micrometer regulator, rail synchronous operation, ensure high precision alignment. 19 inch large screen display contrapuntal line electrode, the alignment more quickly, more elegant appearance

How to Repair your Samsung and LG TV Panel with our Machine 1. using imported circuit and pneumatic fittings, Japan's matsushita PLC controller is adopted in the core, by SMC pneumatic components of precision components. 2. cylinder part adopts horizontal bar higher precision guide rail combination plan, has the state set shift, the characteristics of the deviation. 3. provide a multi-position pulse current systems and control, to meet the different requirements of diversified products for heating power. 4. the high precision temperature control system, using PID self-tuning control scheme, can be a period of temperature heating and temperature compensation function in time, the temperature accuracy to + / - 1 , meet the requirement of maintenance process precision of temperature. 5. 7 inch human-machine interface touch screen control system, which can store multiple brand hot pressing parameters and display the actual temperature curve. 6. the built-in vacuum adsorption system, hot pressing head high precision level control device. 7. the X axis servo control LCD (step) mobile function, can set up multiple IC point coordinates, can also do Y axis moving, after completion of the FOG straight to FOB process. 8. equipped with Japanese high-definition coaxial optical registration system and bring the light system, effective guarantee product registration precision requirements.