Multi Slitter LED Strip PCB Separator Machine Three Group Blade Zero Stress

| Place of Origin: | |

|---|---|

| Brand Name: | |

| Certification: | |

| Model Number: |

| Min Order: | |

|---|---|

| Packaging: | |

| Delivery Time: | |

| Payment Terms: | |

| Supply Ability: | |

| warranty: |

| Slitter: | Multi Slitter PCB Depanelizer | Delivery: | DHL FEDEX UPS |

|---|---|---|---|

| Cutting Stress: | Zero | Cutting Capacity: | Without Limited |

| Industry: | LED Strip | Lead Time: | One Day |

Multi Slitter LED Strip PCB Separator Machine Three Group Blade Zero Stress

Competitive Advantages :

| 1. Separates large numbers of PCBs without fatigue of the operator LED strip |

| 2. Motor driven LED strip LED strip LED strip |

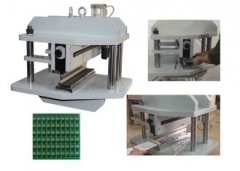

| 3. The PCB is feed between the circular blades where it is seized, transported and separated |

| 4. Different speeds can be selected |

PCB Depaneling Machine Specification:

Machine Size: 40*40*34 cm

Platform size : 150*27*20 cm

The Longest Minimize: No limited

Minimize Speed: 0-400mm/s

Minimize thickness: 1.0-3.5mm

Machine Weight: 45Kg

Why Clients Buy Our PCB Separator

1. Currently, it is the only machine that can guarantee the aluminum plate without deformation after cutting .

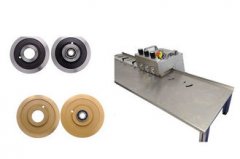

2. With unique cutting method, the circuit board is cut by six blades. It is a group composed of one upper and one lower blade, and is also a cutting unit.

There are A, B, C, three groups. The whole cutting process is divided into three stages from group A blade which cut 10% board then to the group B blade knife cut through groove cutting by group A to complete another 40% .the last 50% is cut by group C blade and finishing.

because each cutting volume is small, the stress produced during the cutting progress declined by more than 50% compared with the traditional cut off at a time.

Thus the edge of the board and its surface are very smooth without warping .

Customers FAQ About PCB Separator

|

1. Q:What is warranty of the machine? A:1 year. |

|

2. Q:How do you offer oversea service? A:We could send engineer to do installation and training for client if needs |

|

3. Q:Can we see your machine in our country? A:Yes, we would like to offer contact details of our clients who are using our machines. |

|

4. Q:Can the blades be sharpened? A:Yes, they could be re-sharpened for 2-3 times. |

|

5. Q:Do you have any certification for this machine? A:YES,We have CE ISO FCC ROHS etc. |

|

6. Q:How do you pack the machine? A:We fix the machine on the plywood base with screws to ensure safe transportation. |

|

7. Q:What is material of blades? A:Japan high speed steel SKH-9 |