|

|

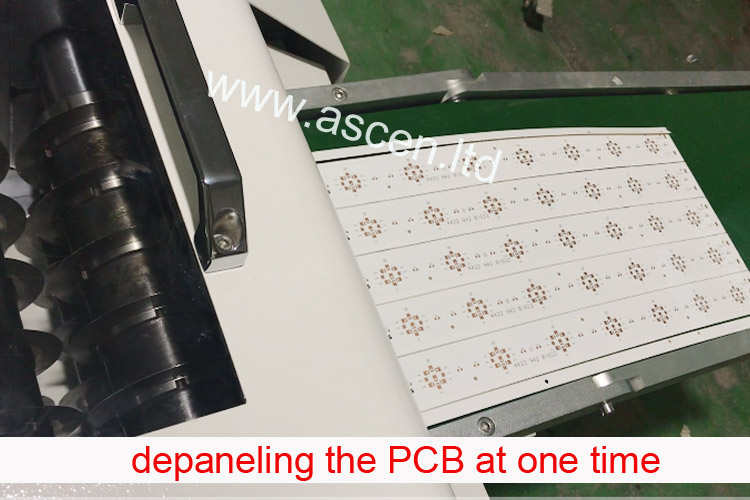

ASCEN technology co.,ltd specializing in the SMT automatic equipment and provide the automatic solution for the smart factory for save more producing cost.

Whether you'd like to get more info on what,why and how we do what we do, need help with what you're creating,would line to partner up or just say hi!

—--- We'd love to hear from you.

Note : Your information detail will not be published. Required fields are marked*