Detailed Product Description

ASCEN technology team is escorted by a vigorous team of humble and patient staff. They enjoy listening to the clients and tailoring automatic assembly solutions up to clients' demand. we dedicated to making quality machine that help our clients operate more efficiently and effectively.If you interested in our complete equipment solution,please go to our engineering web: www.ascen.ltd

Why choose ASCEN aluminum PCB separator depaneling machine than others

Your have to understand not all LED strip PCB separator is the ASCEN PCB separator equipment

ASCEN PCB separator is used for depaneling the LED aluminum PCB panel light bar,with high efficiency without deformation and burrs,greatly saving labor.

Application:

LED board PCB separator depaneling the PCB panel by 6 cutting wheel. The cutting process with the low stress because of the multiple cutting.suit for cutting LED aluminum PCB panel,LED copper substrate, LED light-emitting tube,display panel, LED T8 tube etc.

ASCEN PCB separator with cutting group A, B and C, the PCB board separation according three cutting group, The whole cutting process is divided into three stages from group A blade which cut 20% board then to the group B blade knife cut through groove cutting by group A to complete another 30% .the last 50% is cut by group C blade and finishing, Using this principle, The stress of the cutting process can be reduced by 80% than the traditional one-cut process for the small cutting quantity each time. And the edges of the board are quite smooth after cutting. You will see most of LED PCB separator similar.

Some details about other similar machine that few people know:

Most of time, a lots of people can find the similar LED PCB cutting machine in the network, or you have a lots of supplier can provide you the PCB separator, but not all machine with the same function and same precision with ASCEN LED PCB separator. You have to have a clear understanding that the precision of the machine and the later use of the machine is very important to you.

LED PCB depaneling machine use the above ABC cutting group principle, The machine design and positioning require high precision to keep this ABC cutting group in a straight line. Please know, If there is about 0.1mm error in the ABC cutting group, this 3 upper blade will not in a straight line. When you get a poor machine and working for your PCB board, this 3 upper blade will staggered into the V-score of PCB panel. The PCB panel will get the big burrs and easy to twist after cut. Most of following similar machine, you will feel your PCB bend and easy to twist after use in some time. Please know.

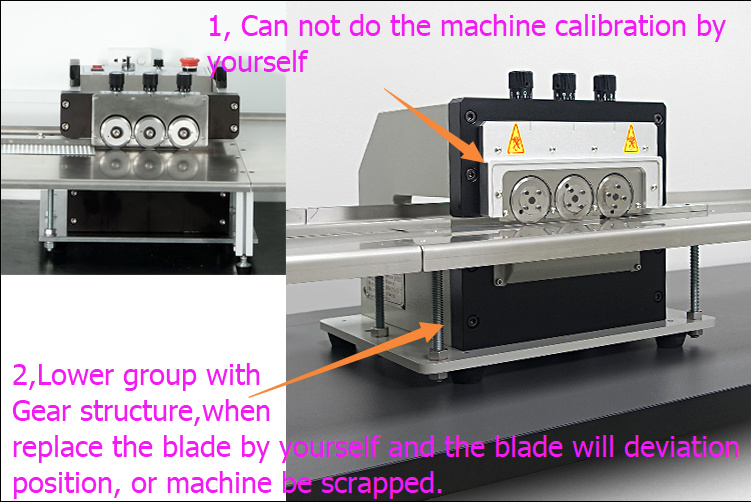

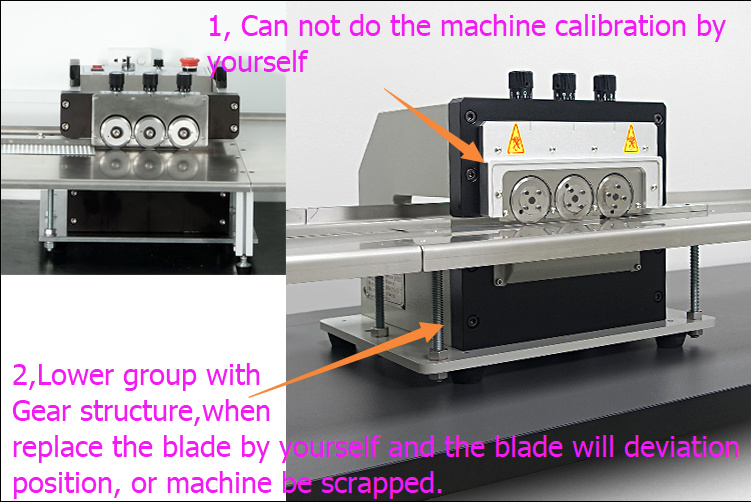

One similar machine as following:

1, the above machine can not do the cutting group calibration by yourself.

When the axle of this machine cutting group wear after some time, this 3 blade will has the error ,you will feel your PCB bend and twist after cut, the worst is that you can not do the calibration by yourself. Most of time, this similar machine supplier will give you a very cheap price to clinch a deal, but after some time and you need do the after-sale serve ,they will ask you to purchase a new one again. In fact, it is not a low cost for using this type machine.

2, this machine Lower group with the gear structure,when you replace your blade by yourself, you need dismantling a lots of small part, you as a non-professional repairman,when you finish the replacement, your lower blade will deviation position or with the big error. After that, your machine can not separate your PCB board in a good state.Basically, your machine is dead. You almost need purchase a new one again.

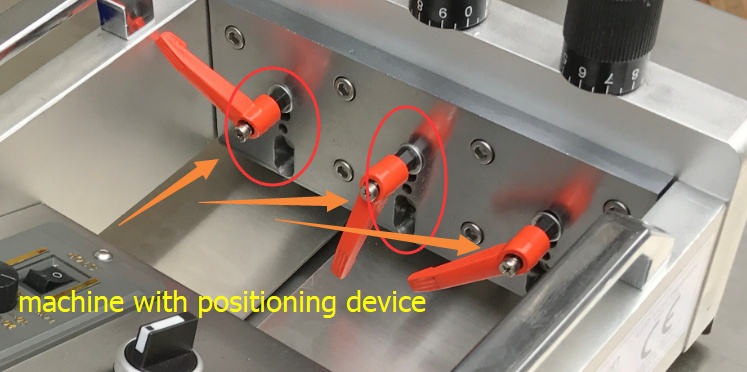

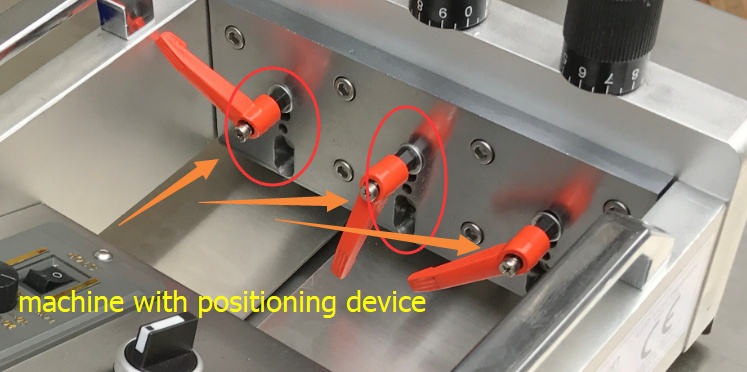

Another similar machine as following:

The above type LED PCB V cut separator is not a high precision machine, this similar PCB separator has no the positioning plate to ensure the cutting group accuracy, and you can not correct the machine by yourself.

Most of time, your supplier will quote a very cheap price to deal with you. The supplier will do a complete calibration before delivery,when you working for some time and need to replace the blade,because the machine have no the positioning plate, when your replace the blade by yourself,it is very hard to keep the machine ABC cutting group blade be a straight line.if the 3 blade get about 0.2mm error, you can get a lot of burr after separate your PCB panel. In general, when you need replace the blade for your machine, your supplier will hope you can pay some cost and let them come to the local for help you.But that is a big cost for that. Otherwise, your machine will work in a bad precision. Please know.

About the ASCEN LED aluminum PCB separator advantage:

1, ASCEN PCB separator has the positioning plate device to keep the ABC cutting group be a straight line. No matter how many time you replace the blade, you only need to tighten the screw, this 3 cutting blade must keep a straight line.

2, The upper cutting group of ASCEN PCB separator has the XY axle adjustment function.

When your cutting group wear after working for long time, your can do the fine tuning adjustment for each blade by yourself to keep the ABC cutting group be a straight line.and don’t need ask anyone for help.it greatly saves the time for the machine to stop production.Please know.

Most of time, purchase the machine we need more care about the machine failure rate and the machine maintenance cost. We don’t advise you choose the cheapest machine, get a good using and easy maintenance machine is ok , if that is a poor machine, when your machine stop to work for few days, your production cost will greatly increase. If need purchase a new one again or pay more cost for after-sale serve, that is not a good idea.

That is why we advise you choose the good precision machine. Any question about the ASCEN PCB separator ASC-700N model, please inquiry us in any time.

The standard ASCEN PCB separator depaneling machine 700N model , please click here for LED PCB separator

ASCEN technology co.,ltd specializing in the SMT automatic equipment and provide the automatic solution for the smart factory for save more producing cost.