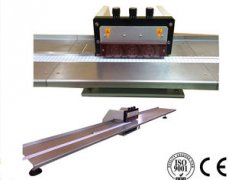

metal V Cut PCB Depaneling Machine Pneumatic Driven Solid Iron Structure

| Place of Origin: | |

|---|---|

| Brand Name: | |

| Certification: | |

| Model Number: |

| Min Order: | |

|---|---|

| Packaging: | |

| Delivery Time: | |

| Payment Terms: | |

| Supply Ability: | |

| warranty: |

| Unique Frame: | Solid Iron Structure | Components Height: | 70mm |

|---|---|---|---|

| CEM Material: | Metal PCB Board | Application: | All Type PCB |

| Inner Packing: | Film | Guarrantee: | One Year |

Metal V Cut PCB Depaneling Machine Pneumatic Driven Solid Iron Structure

pcb depaneling machine Features

1. Pneumatically driven and electric control, sample design. There have sensor device in the machine, cuttting board one time with lowest cut stresses. SM-4000 apply for separate precise SMD PCBA or thin plates.

2. Cutting with the double straight knives, it is especially suitable for the segmentation of precision SMD sheet and aluminum PCB.

3. The inner stress when cutting will be under 180ue, in case of a solder crack and the damage of precision components.

4. The straight knife type separator machines were designed to separate pre-scored panel boards carefully, without bending or tension stress. Even sensitive SMD-components like ceramic capacitors will not be damaged by the separate process, improve products quality.

5. Due to the special design of the blade, boards with high components placed close to the edges can be separated safely. Based on a proven method of separating, wedge-shaped knives are used to cut the panels within the groove. This enables boards of less than 1 mm thickness to be separated safely and without creating stress

Technical Data

1. 100% responsible for quality

2. 12 years experience

3. Free sharpening for blades within 3 months

4. 1 day delivery

5. 24 hours fast response

6. Largest manufactory in South China

| Model | ||

| Max.cutting length | 130mm 200mm | 330mm |

| Outside size(L×W×H) | 500×300×440mm | 700×300×400mm |

| Cutting thickness | 0.3-3.5mm | 0.3-3.5mm |

| Working air pressure | 0.50-0.70Mpa | |

| Weight | 80 kg 100kg | 130kg |

Most of our customers Questions about PCB Depaneling Mahcine

1. Q:How do you pack the machine?

A:We fix the machine on the plywood base with screws to ensure safe transportation.

2. Q:Do you have any certification for this machine?

A:YES,We have CE ISO FCC ROHS etc.

3. Q:Can the blades be sharpened?

A:Yes, they could be re-sharpened for 2-3 times.

4. Q:How do you offer oversea service?

A:We could send engineer to do installation and training for client if needs.