Aluminium T8 Tube PCB Depaneling Machine 1200mm Length Burring - Free

| Place of Origin: | |

|---|---|

| Brand Name: | |

| Certification: | |

| Model Number: |

| Min Order: | |

|---|---|

| Packaging: | |

| Delivery Time: | |

| Payment Terms: | |

| Supply Ability: | |

| warranty: |

| LED Application: | 1200mm LED T8 T5 | Certification: | CE ISO |

|---|---|---|---|

| Condition: | New | Lead Time: | One Day |

| Name: | PCB Depaneling Machine | Speed: | Adjustable |

Aluminium T8 Tube PCB Depaneling Machine 1200mm Length Burring - Free​

LED Tube 1200mm Aluminium YES-6 PCB Depanelizer Machine Characters:

T8 T5 LED Tube strip pcb separator manufacturer supply you the burring-free and stress-free pcb separation,make you led tube lighting up.

| Cutting Lenght : | Unlimited. |

| Voltage : | 110V / 220V |

| Certificates: | CE Mark |

| Weight : | 85 Kg / 98 Kg . |

| Platform length: | 1.5 M / 2.4 M |

| Cutting Board : | v-cut pcb board , FR4 board . LED Aluminum board |

| Dimension: | 958*506*333mm / 1020*506*333mm |

| Cutting Speed : | 80,120, 200, 400mm/s |

| Cutting Thickness: | 0.2-5mm |

| Voltage: | 230V/50Hz(110V/60Hz) |

| Power: | 40W |

Aluminium PCB Depaneler Feature:

1. It is electric control,the straight knife type separator machines were designed to separate pre-scored panel boards carefully, without bending or tension stress. Even sensitive SMD-components like ceramic capacitors will not be damaged by the separate process. Due the special design of the knives also boards with high components placed closed to the edages can be separated safely.

2. No vibration during the process to prevent damage to precise PCB

3. Gap for insertion of the board can simply be adjusted by means of the adjusting knob , low friction design is applied

4. Lower knife height adjustable, no thin plates are required after re-sharpening the cutting blade

5. Operation and maintenance can be done also by unskilled personnel.

V Groove PCB Depaneling Machine Structure and working :

1. With unique cutting method , the circuit board is cut by six blades . It is a group composed of one upper

and one lower blade , and is also a cutting unit. There are A, B, C, three groups. The whole cutting

process is divided into three stages from group A blade which cut 40% board then to the group B blade

knife cut through groove cutting by group A to complete another 40% .the last 20% is cut by group C

blade and finishing. because each cutting volume is small, the stress produced during the cutting

progress declined by more than 80% compared with the traditional cut off at a time. Thus the edge of the

board and its surface are very smooth without warping . Currently, it is the only machine that can

guarantee the aluminum plate without deformation after cutting .

2. because of the multiple cutting, cutting process is very smooth and greatly improves the capability of

position of V-CUT groove . Even if with shallow slot V-CUT groove the board won t jump out of blade,

avoiding adverse.

3. Because cutting force of the blade is small. abd with high speed steel material which is imported from

the Swedish. durability of the blade greatly improved , and the lifetime can be one year or more when

cutting the aluminum board.

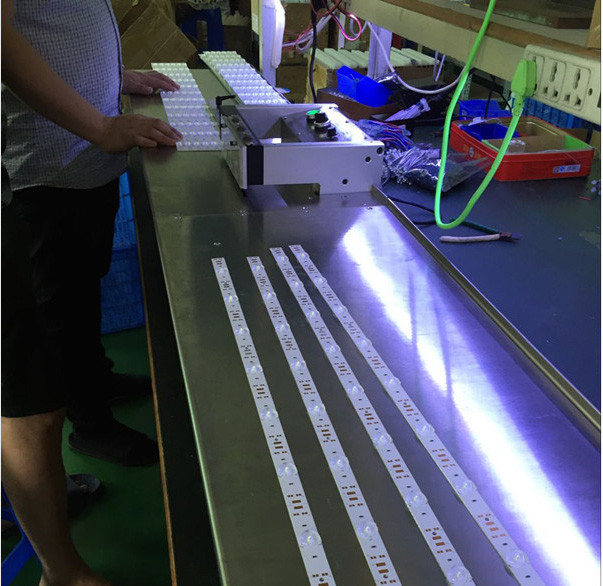

Customers Aluminium PCB Test by Our PCB Separator YES6

Our old customer Mr.Jones from Canada design a new led strip and bring samples to our factory to test by the PCB Depanelizer