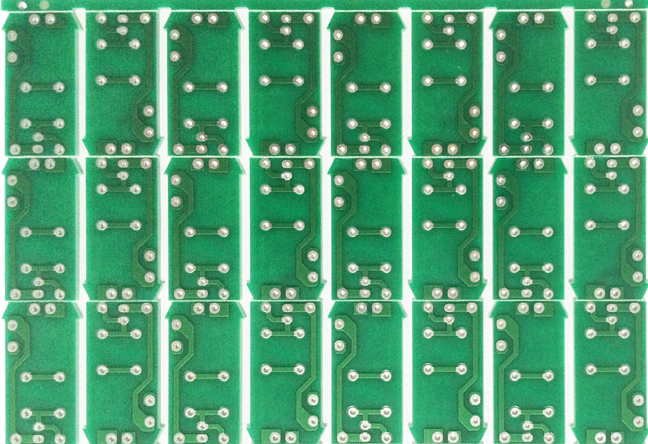

SMT Machinery V CUT Groove PCB Depaneling Tool Blade Moving For Rigid PCB

| Place of Origin: | |

|---|---|

| Brand Name: | |

| Certification: | |

| Model Number: |

| Min Order: | |

|---|---|

| Packaging: | |

| Delivery Time: | |

| Payment Terms: | |

| Supply Ability: | |

| warranty: |

| Type: | Blade Moving | Suitable: | Rigid PCB |

|---|---|---|---|

| Efficiency: | Without Burring | Application: | All Type PCB |

| Driven Type: | Motorized | Guarrantee: | One Year |

SMT Machinery V CUT Groove PCB Depaneling Tool Blade Moving For Rigid PCB

SMT Machinery PCB Depanelizer important specialty:

1. The feeding speed is adjustable with 500mm/s and 300mm/s. If the speed is fast enough, the quality is improved for the board is cut without burrs and rough selvedge.

2. Equipped with electronic eye safe sensor,can automatic stop when operator hands near the blades,ensure the worker safety.

3. The feed distance of the knife wheel is from 0 to 500mm(the tool length can be customized ) . The height of the knife wheel is fine-tuning from 0 to 2mm,so that it is suitable for PCB of various kinds of thickness and the depth of V-CUT groove. The height of work station is regulable from 0 to 50mm.

4. The tailgate depth range: unlimited. The largest plate cutting width: unlimited,the maximum cutting length: 500mm, the plate thickness: 0.25-3.5mm. The thickness between V groove: 0.25-2.0mm.

5. The machine can be in supporting use of a complete set of conveyor belt,which is convenient for the cut PCB to be send out automatically.

PCBA PCB Depaneling Machine Technical Characteristics :

More details and machine working video kindly contact us by mail or phone call.

| PCB singulation machine size | 770*510*450mm |

| Max. PCB singulation length | 460 or 600 mm(on request custom made) |

| PCB singulation thickness | 0.6-3.5 mm |

| PCB singulation feed rate | 100,200,300,500 mm/sec |

| Model |

Customers FAQ About PCB Separator :

1. Q:Do you have any certification for this machine?

A:YES,We have CE ISO FCC ROHS etc.

2. Q:What is warranty of the machine?

A:1 year.

3. Q:How do you pack the machine?

A:We fix the machine on the plywood base with screws to ensure safe transportation.

4. Q:What is life time of machine blades?

A:About 6-12 months.

5. Q:What is material of blades?

A:Japan high speed steel SKH-9

6. Q:Can the blades be sharpened?

A:Yes, they could be re-sharpened for 2-3 times.

7. Q:How do you offer oversea service?

A:We could send engineer to do installation and training for client if needs.

8. Q:Can we see your machine in our country?

A:Yes, we would like to offer contact details of our clients who are using our machines.